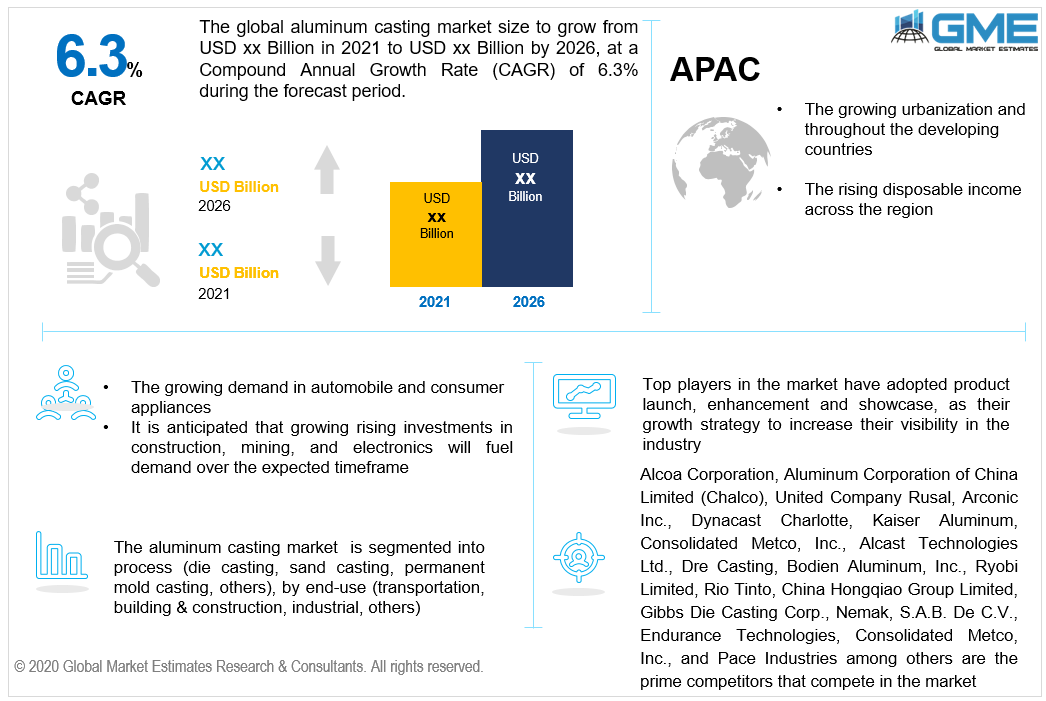

Global Aluminum Casting Market Size, Trends, and Analysis - Forecasts To 2026 By Process (Die Casting, Sand Casting, Permanent Mold Casting, Others), By End-Use (Transportation, Building & Construction, Industrial, Others), By Region (North America, Asia Pacific, CSA, Europe, and the Middle East and Africa); End-User Landscape, Company Market Share Analysis & Competitor Analysis

Aluminum is lightweight and has high thermal, excellent strength and electrical conductivity, superior workability, mild reflectivity, and attractive appearance, guaranteeing that iron and steel are usually cast over aluminum. Casting is the method through which raw aluminum is processed into goods, by pouring and heating. As opposed to any other alloy products, the process helps the manufacturer to produce parts at a higher and faster pace. The products that are made have become corrosion-resistant, flexible, and can be used for a wide variety of applications with the aid of the casting process. The pouring of aluminum composites as a liquid metal requires aluminum casting. Aluminum is heated so that the fluid-structure and then filled molds are transformed over it. The mold must be in the exact shape and well finished, as it directly affects the finished aluminum casting.

The growth of the aluminum casting market is driven by increasing interests in buyer equipment, high interests in building, electronics, and mining expansion in projects, and increasing economies. With the expansion of the automotive market, demand for aluminum casting from the general transport segment is anticipated to accelerate. The increasing demand for aircraft in developing economies such as India and China is also driving the growth. In the industry, aluminum cast materials are typical jet engines or aircraft engine parts. The worldwide sales of lightweight vehicles in May 2019 reached 17.4 million units, as per the Federal Reserve Bank of St. Louis. It is predicted that rising demand for general utility and sports utility vehicles will boost product demand in the U.S.

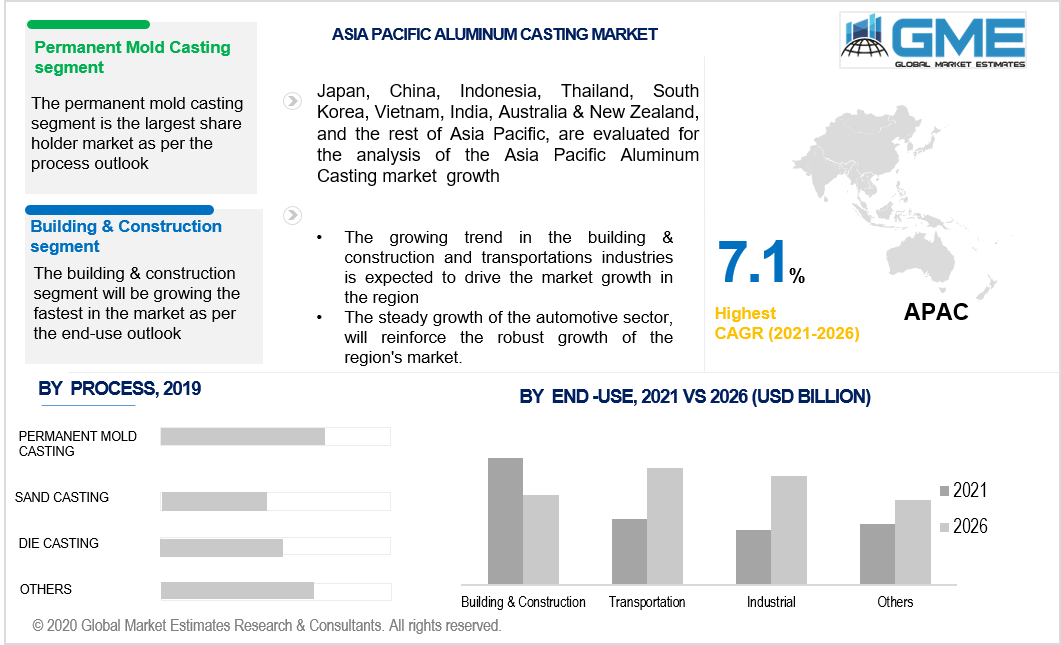

In 2019, the permanent mold casting segment accounted for the largest share of the revenue. Permanent mold casting is a technique using a single mold structure made of high-temperature resistant material such as die steel cast iron to produce a large number of cast items. The permanent mold casting finished product has a superior finish with high dimensional resistance, making it suitable for the production of motorsport and recreational vehicle parts. In the coming years, the growing demand from the motorcycle segment is likely to offer aluminum permanent mold casting producers sufficient opportunities.

The die casting segment is anticipated to grow over at a substantial CAGR during the projected timeframe, due to the increasing demand for aluminum casting products in the automotive industry. Die casting is being used to produce different automobile components, such as flywheels, engines, gears, and cylinders, which are used for the mass production of automobiles in high-end vehicles. This is due to factors such as the low cost of die casting and the worldwide establishment of strict CO2 emission rules.

During the forecast era, the building & construction segment is anticipated to boost at a high CAGR, due to the rising use of aluminum casting products in homes. In applications ranging such as roofing, curtains, door handles, curtain walling, aluminum casting may be used. Due to evolving customer tastes and the advantages of aluminum, such as lightweight and aesthetic appeal, the growing substitution of iron and steel is expected to drive the demand in the coming years.

From 2021 to 2026, the transportation application segment is anticipated to dominate the market for Aluminum Castings. This is attributed to the increasing demand for lightweight cars worldwide, which has led to the substitution of steel and iron parts with aluminum products in cars. The increasing demand in the transport sector for aluminum cast components is due to the increasing popularity of lightweight vehicles with better fuel efficiency. As aluminum cast products are used in the manufacture of jet or aircraft engines, growth in the transportation segment is also assisted by the growing demand for aircraft. The need for new jet engines is likely to be driven by the rising demand for new aircraft, thereby positively impacting the aluminum casting market over the coming years.

In the expected timeframe in terms of sales, the Asia-Pacific region is the leading market shareholder and also indicates a significant CAGR rate over the forthcoming years. One of the key factors driving the market growth is the trend in the building & construction and transportation industries. The presence of leading producers in countries such as China and Japan promote the growth of the market for aluminum casting amid rising automotive and industrial production. Moreover, the manufacturing of automotive vehicles, combined with the steady growth of the automotive sector, will reinforce the robust growth of the region's market.

Furthermore, in the expected timeframe in terms of sales, the North American region is the second-most leading market shareholder followed by Asia-Pacific. Due to the strict pollution regulations in the United States and the growth of the manufacturing sector in Mexico, it is motivated by factors that have contributed to the market. The increasing use of aluminum in automotive production has a major and direct effect on the cast products industry. North America is one of the largest vehicle aluminum casting markets in the world and is therefore experiencing healthy growth over the projected period.

Alcoa Corporation, Aluminum Corporation of China Limited (Chalco), United Company Rusal, Arconic Inc., Dynacast Charlotte, Kaiser Aluminum, Consolidated Metco, Inc., Alcast Technologies Ltd., Dre Casting, Bodien Aluminum, Inc., Ryobi Limited, Rio Tinto, China Hongqiao Group Limited, Gibbs Die Casting Corp., Nemak, S.A.B. De C.V., Endurance Technologies, Consolidated Metco, Inc., Rockman Industries Ltd., Eagle Aluminum Cast Products, Martinrea Honsel, Ningbo Innovaw Mechanical Co., Ltd., La Aluminum Casting Company, and Pace Industries among others are the prime competitors that compete in the market.

Please note: This is not an exhaustive list of companies profiled in the report.

In November 2020, Alcoa Corporation signed an agreement with Kaiser Aluminum Corporation to sell its Alcoa Warrick LLC’s rolling mill business for approximately USD 670 million.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Aluminum Casting Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Aluminum Casting Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS