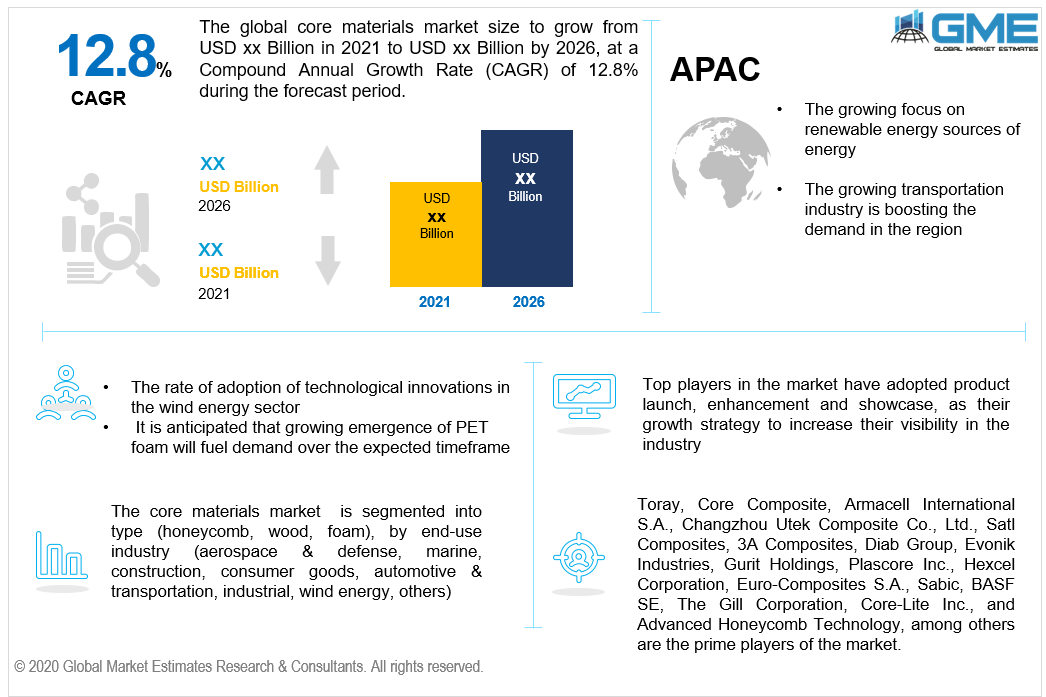

Global Core Materials Market Size, Trends & Analysis - Forecasts To 2026 By Type (Honeycomb, Wood, Foam), By End-Use Industry (Aerospace & Defense, Marine, Construction, Consumer Goods, Automotive & Transportation, Industrial, Wind Energy, Others), By Region (North America, Asia Pacific, CSA, Europe, and the Middle East and Africa); End-User Landscape, Company Market Share Analysis & Competitor Analysis

The materials used in aviation and wind energy equipment to increase the performance of the materials are core materials. Usually, core materials are relatively low-strength materials; however, their higher thickness provides the sandwich composite a high bending rigidity with low density. Core materials are used in a wide range of industries, including marine, wind, and aerospace. The core material is placed between the renovating layers so that it is fixed to either side of the core material, providing a greater advantage.

Core materials are commonly used for high-performance goods to produce stiff, strong, and lightweight structures. The growth of the market is anticipated to increase due to increasing demand from the wind energy industry along with rising investments in the marine sector, which is driving the market growth for core materials.

Growing air traffic due to the growing existence of low-cost carriers worldwide needs, in addition to fulfilling the requirements of newer carriers joining the aerospace industry, to boost the fleet sizes of existing airline operators. Some of the main factors anticipated to push market growth during the forecast period are the rising use of composites in the aerospace industry and the increasing demand for lightweight core materials. Moreover, the increasing usage of multilayer balsa wood for a wide range of applications, such as marine and aerospace applications, is one of the significant factors driving the growth of the market. The global core materials market is rising worldwide because of its growing demand from composite product manufacturers.

The development of new methods of manufacturing honeycombs has led to technical advances. These techniques include the heated press system and the sorting of vacuum bags. Growing focus on renewable energy sources is anticipated to steer the demand is driving the growth. A cost-advantage strategy is used by players in the market for their products. Strict environmental issues due to government regulations and high material costs are likely to hamper market growth throughout the forecast period.

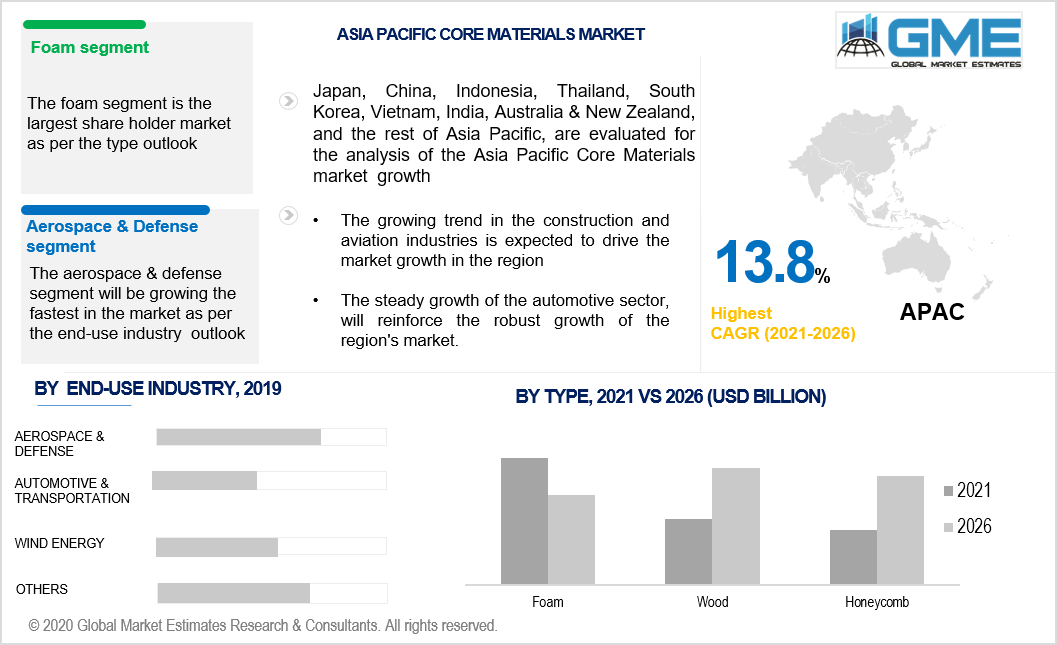

The global core materials industry is fragmented into honeycomb, wood, and foam, depending on the form. During the projected timeframe, the foam segment is anticipated to expand at a high CAGR. Foams are simple to process and form and offer an outstanding strength-to-weight ratio, making them the core material's most common type. It is further subdivided, into SAN, PEM, PVC, PEI, and PTI, among others. These are commonly used in applications such as wind turbines and blades for wind energy, and boat hulls, among others. Moreover, foam cores are preferred in industrial applications.

In the coming years, the advent of PET foam and developments aimed at reducing the cost of end goods are likely to give opportunities for the market to expand. PET foam is thermoformable, provides high autoclave processing heat resistance, remains ductile at cryogenic temperatures, and has excellent clarity of the radar. It is widely used in radomes and to insulate cryogenic tanks in aircraft interiors. The quickest increasing foam material is PET foam, and it substitutes balsa and PVC foam in some applications.

During the projected timeframe, the wind energy segment is projected to hold a major market share. In the wind energy end-use industry, the reduced weight of the required high-strength structure makes the use of core materials significant. Some of the factors driving the market growth are the rising demand for cost-effective & environment friendly generation systems and materials used in blades that need to be lightweight to make cutting easier. In the wind blade category, the size of wind blades is growing, which will push the use of core materials.

Owing to the rising demand for lightweight materials in the aerospace industry, Aerospace & Defense is anticipated to witness the fastest segment during the projected timeline. Air travel between major business hubs is constantly rising over the years and this growth is projected to continue over the forecast timeframe. It is expected that the rising aerospace industry will boost demand for composites, thus fueling the core materials market. The demand for new aircraft is projected to exceed more than 40,000 by 2036, as per Boeing.

North America is expected to hold the largest market share in terms of revenue over the forecast timeframe. The increasing overall production of vehicles in the area is propelling the market. The U.S. is anticipated to be North America's largest construction sector and is projected to have the highest number of construction sites. Moreover, the increasing number of wind turbine installations in the region is driving market development.

The Asia-Pacific region is projected to expand at a high CAGR in terms of revenue over the forecast timeframe. The key reasons for the high utilization of core materials are the growing installation of wind power and the increasing transportation sector in the country. In most of the major economies, the production of non-essential commodities has been brought to a stop. Moreover, the rising level of construction activity in the commercial and residential construction sectors is increasing. The growing construction industry is driving the regional market growth in emerging countries, including India, Japan, South Korea, China, and Singapore, among others.

Some of the key players operating in the core materials market are Toray, Core Composite, Changzhou Utek Composite Co., Ltd., Satl Composites, 3A Composites, Diab Group, Evonik Industries, Gurit Holdings, Changzhou Tiansheng New Materials Co. Ltd., The Gill Corporation, Euro-Composites S.A., Plascore Inc., Sabic, BASF SE, Hexcel Corporation, Armacell International S.A., Jiangsu Yueke New Materials Co., Ltd., Core-Lite Inc., And Advanced Honeycomb Technology, among others.

Please note: This is not an exhaustive list of companies profiled in the report.

In April 2020, the revolutionary Ultramid Balance material solution from BASF SE to create a new rear bumper stay, an automotive product designed to protect the underbody of Molten vehicles, recognized as a Japanese global supplier of sporting goods and automotive components. It has been used in Mazda's newly introduced Mazda 3 & CX-30 car models

In December 2019, Gurit Holding AG signed a supply agreement with a Chinese manufacturer of wind turbine blades to supply core materials to foreign and domestic OEMs.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Core Materials Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Core Materials Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS