Global FRP Vessels Market Size, Trends & Analysis - Forecasts to 2026 By Fiber (Glass, Carbon, and Others); By Resin (Epoxy, Polyester, and Others); By Application (Chemicals, Automotive & Transportation, Industrial, Water & Wastewater, Oil & Gas and Others); By Region (North America, Europe, Asia Pacific, MEA, and CSA); End-User Landscape, Vendor Landscape, and Company Market Share Analysis & Competitor Analysis

Fiberglass-reinforced plastic (FRP) is a modern composite material primarily used to build chemical plant equipment such as vessels, tanks, various types of piping structures, and other industrial equipment. FRP carries some excellent conventional properties such as high corrosion resistance, superior properties of the composite, low maintenance investments, and long shelf life of the product. These properties are not beatable as compared to other existing materials which made it popular in various chemical and industrial applications.

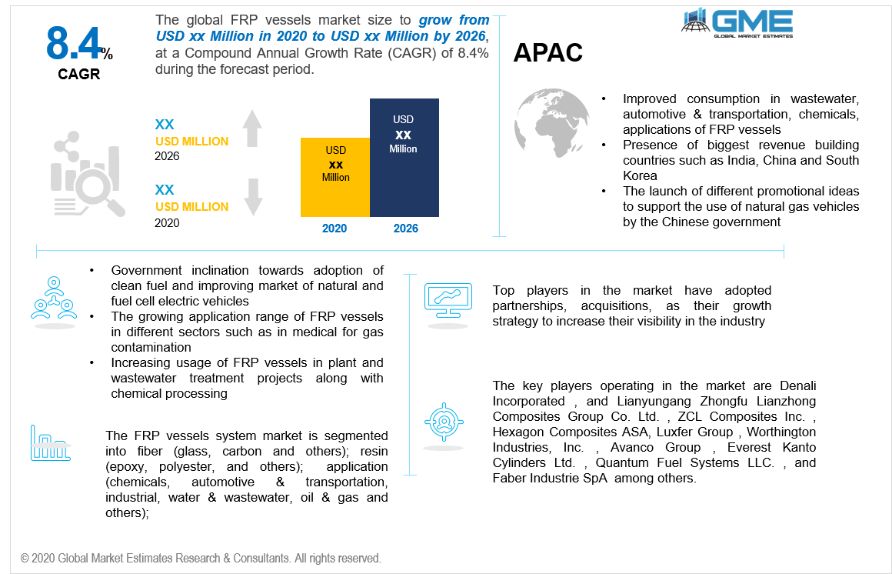

The studies performed by GME showed the FRP vessel market is projected to show trajectorial growth in the middle of 2020-2026 at a CAGR of 8.4%.

Government inclination towards adoption of clean fuel and improving market of natural and fuel cell electric vehicles are the factors expected to boost up the FRP vessels market in coming years. The growing application range of FRP vessels in different sectors such as in medical for gas contamination and also in tanks used in scuba diving is fueling up the demand for FRP vessels. Increasing usage of FRP vessels in plant and wastewater treatment projects along with chemical processing is responsible to build the demand for the product in coming years also.

However, the sudden arrival of the global pandemic has severely affected the sales of natural and fuel cell vehicles resulting in the reduction of the global FRP vessel market.

The FRP vessels based on the type of fiber used can be explained as glass, carbon, and others. Glass segment holds the largest market of FRP vessels in terms of both value and volume. Glass fiber offers various properties such as flexibility, strength, durability, resistance from high temperature, heat and moisture are triggering the popularity of the segment in various end-users. Glass segments is known to serve in wind energy, construction & infrastructure, marine & transport, pipe & vessels and among other industries. On the other hand, carbon fibers are comparatively expensive and used in high end-application industries such as aerospace, sports goods, and industrial parts.

Epoxy, polyester, and others are the categorization of the FRP vessels based on resins. Polyester is a combination of polyhydric or multi-hydroxyl alcohol with organic acids. The polyester resin does not expand when exposed to high temperature and displays good electrical, mechanical and heat resistance properties which made it to build the fastest growing business in China automotive & chemical industries. However, COVID-19 has severely impacted the demand of the segment in the APAC region due to the lockdown imposed by the government.

Chemicals, automotive & transportation, industrial, water & wastewater, oil & gas, and others are the application list of FRP vessels. Water & wastewater dominated the FRP vessels market and expected to maintain its dominance in coming tenures also. Composite vessels are used for the storage of potable water and wastewater. Wastewater contains various contaminants and solid wastes of different densities, sizes, and hardness which are prone to disfigure the tank from inside. Therefore FRP vessels are used that offer excellent characteristics such as high strength, durability, and resistance from corrosion that are more likely to build the product market in the wastewater storage application.

Asia-Pacific is estimated to show the highest market of the FRP vessel market owing to improved consumption in wastewater, automotive & transportation, chemicals, and oil & gas industries applications. India, South Korea, and China are among the highest revenue builder nations of the FRP vessel market. However, China is turned out to be the biggest consumer of the FRP vessel, especially in the automotive & transportation sector. The launch of different promotional ideas to support the use of natural gas vehicles by the Chinese government is also expected to trigger the growth of the FRP vessel market in the aforementioned duration.

The key players operating in the market include Denali Incorporated and Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd., Hexagon Composites ASA, ZCL Composites Inc., Everest Kanto Cylinders Ltd, Worthington Industries, Inc., Avanco Group, Luxfer Group, Quantum Fuel Systems LLC., and Faber Industrie SpA among others.

Please note: This is not an exhaustive list of companies profiled in the report.

In July 2020, Hexagon Purus got its initial project from a major US hydrogen fuel supplier to provide hydrogen transportation modules in the US region. The purchase list for the transportation module is comprised of hexagon’s proprietary, lightweight, 500 bar pressure vessel, type 4.

In November 2020, Hexagon Purus signed a multi-year agreement with Everfuel. The agreement aims to deliver multiple units of a newly launched 45 foot, hydrogen distribution system. The agreement also covers the design, production, and delivery of the system to Everfuel at a cost of approx. EUR 14 million through the year 2025.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global FRP Vessels Market has been studied from the year 2017 till 2026. However, the CAGR provided in the report is from the year 2018 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply side analysis for the FRP Vessels Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the companies and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS