Global Industrial Centrifuge Market Size, Trends, and Analysis - Forecasts To 2026 By Type (Sedimentation Centrifuge (Clarifier /Thickener, Decanter Centrifuge, Disc Stack Centrifuge, Hydro cyclones and Other Sedimentation Centrifuges) and Filtering Centrifuge (Basket Centrifuge, Scroll Screen Centrifuge, Peeler Centrifuge, Pusher Centrifuge, Inverting Basket Centrifuge, Vibratory Centrifuge)), By Mode of Operation (Batch Centrifuge and Continuous Centrifuge), By Design (Horizontal Centrifuge, Vertical Centrifuge), By End-User (Chemical Industry, Food and Beverages Industry, Metal Processing Industry, Mining Industry, Pharmaceuticals and Biotechnology Industry, Power Industry, Pulp, and Paper Industry, Wastewater Treatment Plants, Water Purification Plants), By Region (North America, Asia Pacific, CSA, Europe, and the Middle East and Africa); End-User Landscape, Company Market Share Analysis & Competitor Analysis

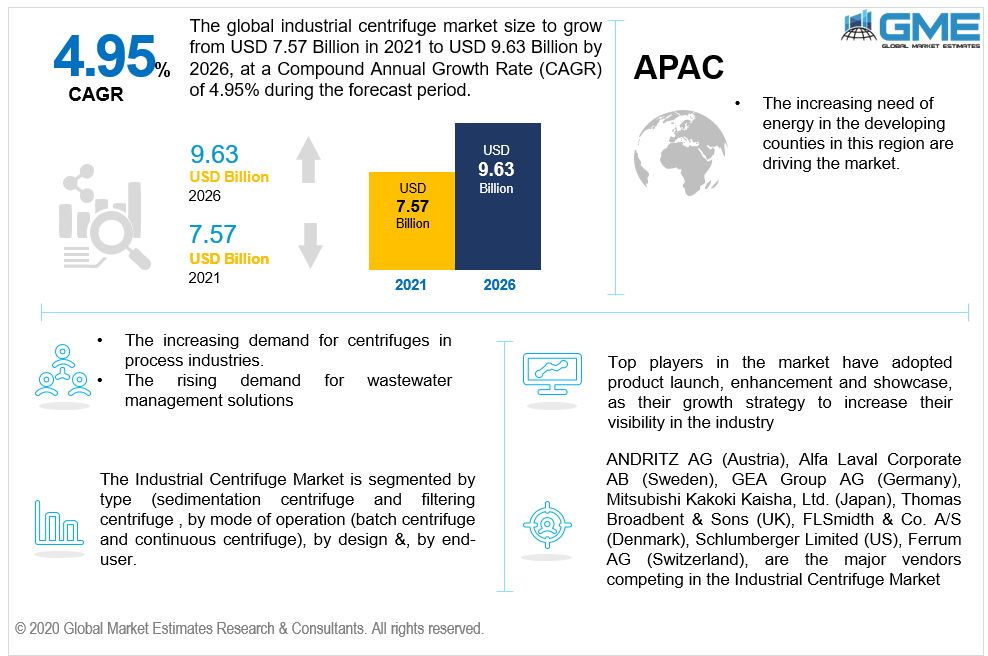

Major driving factors like, the increasing need to manage wastewater globally, the increasing use of centrifuges in various process industries is leading this market to a greater future. The global market is estimated to reach more than USD 9.63 billion by 2026.

The industrial centrifuge is a mechanism used to separate particles of fluids. It can do solid-liquids, liquids-liquids, and liquid-liquid-solid separations. The growing demand from process industries along with the growing need for wastewater management solutions are supporting the market growth. The industrial centrifuge is used for the separation of two or three-phase systems and has a range of other applications in heavy industries.

The process industries globally are implementing different types of centrifuge machines for the separation of two or three immiscible phases. Chemical processing, pharmaceutical industry, metal processing, biotechnology sector, mining and mineral processing, food processing, and fuel and biofuel industries are the major end-users for centrifuge equipment. Although the high cost of such a machine acts as a restraint in this market, the irreplaceable use of it is what leads this market to a great future.

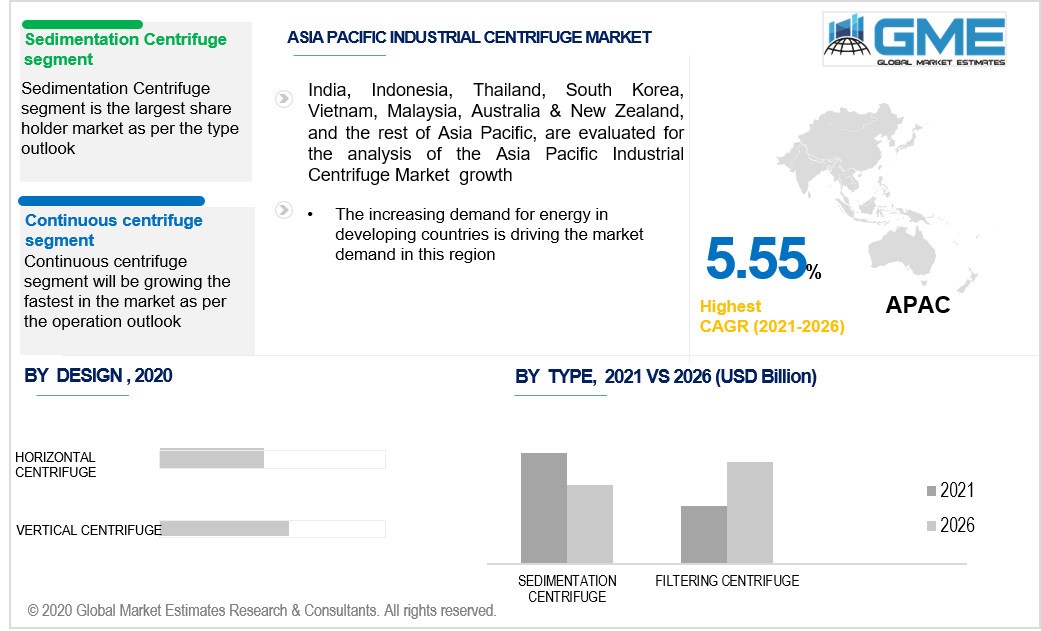

According to type analysis, the market is considered into sedimentation and filtering centrifuge. The category of the sedimentation centrifuge is expected to be the fastest-growing as well as the largest shareholder over the estimated timeframe mainly due to its wide range of industrial applications, the ability to achieve high speeds in less time.

Apart from these, the growing demand for oil and gas is leading to an increased oil and gas explorations, which is therefore increasing the demand for industrial centrifuge, as the centrifuge is irreplaceably essential for this industry. And as the centrifuge can separate liquids and solids, it is has a high demand in wastewater management. More specifically, all these uses call for high power and high-speed centrifuges, that is the sedimentation centrifuges.

According to the mode of operation analysis, the two segments are batch centrifuge and continuous centrifuge. The continuous component segment will be a prominent segment in terms of growth rate between 2021-2026. The key factors that lead to this growth are its continuous mode while using it and the fact that they do not require a batch process that is more time consumable. In most industries, centrifuges are used for separating and purifying highly commercial liquids. The continuous centrifuges lessen the wastage and separate a fair amount of product in less time, which increases the demand in this centrifuge market.

Based on the design, the market can be divided into two categories: vertical centrifuge and horizontal centrifuge. Between these, a vertical centrifuge is expected to dominate the market. The vertical centrifuge offers different properties such as high speeds and high efficiency of separating the inputs.

Also, the vertical centrifuge is less expensive and also it weighs less than the horizontal centrifuge. Moreover, the maintenance cost of vertical centrifuge is also a lot less than that of the other type, which leads this market to grow.

Based on the study, the end-user market can be divided into several categories: chemical industry, water purification plants, food and beverages industry, wastewater treatment plants, metal processing industry, pulp and paper industry, mining industry, power industry, and pharmaceuticals and biotechnology industry among others.

Out of all these, the power industry is expected to grow at the largest pace during the forecasting period due to, the growing demand for energy, especially in the emerging countries of Asia. The increasing oil and gas exploration activities and growing investments and the establishment of new power plants along with updating of old power plants are boosting the market growth.

North American region holds the leading position in the market in terms of revenue and share. The U.S. plays a major role in the region and supports the regional growth between 2021-2026, due to its developed infrastructure and presence of leading end-users in the region. The presence of leading Oil companies such as Exxon Mobil, Conoco Phillip’s, and EOG Resources are boosting regional growth. The rapid growth in the food & pharma industry in the region is also supporting the market growth. But the APAC region is also expected to grow significantly during this period, mainly due to the growing demand for energy in the developing countries of this region.

ANDRITZ AG, Pneumatic Scale Angelus, Alfa Laval Corporate AB, B&P Littleford, GEA Group AG, US Centrifuge Systems, Mitsubishi Kakoki Kaisha, Ltd., Dedert Corporation, Thomas Broadbent & Sons, Comi Polaris Systems, Inc., FLSmidth & Co. A/S, Elgin Separation Solutions, Schlumberger Limited, HAUS Centrifuge Technologies, Ferrum AG, SPX Flow Inc., Flottweg SE, Gruppo Pieralisi - MAIP S.p. A, SIEBTECHNIK TEMA, and HEINKEL Drying & Separation Group among others are the major vendors manufacturing and supplying Industrial Centrifuge products.

Please note: This is not an exhaustive list of companies profiled in the report.

In 2020, GEA Group AG introduced the ‘GEA sludge Decanter proline’, which got much attention in this market. It allows the harvest of bacteria after the fermentation, the powder acquired from this process is probiotic and used in various sectors like food, agriculture, biotechnology, etc.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Industrial Centrifuge Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Industrial Centrifuge Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS