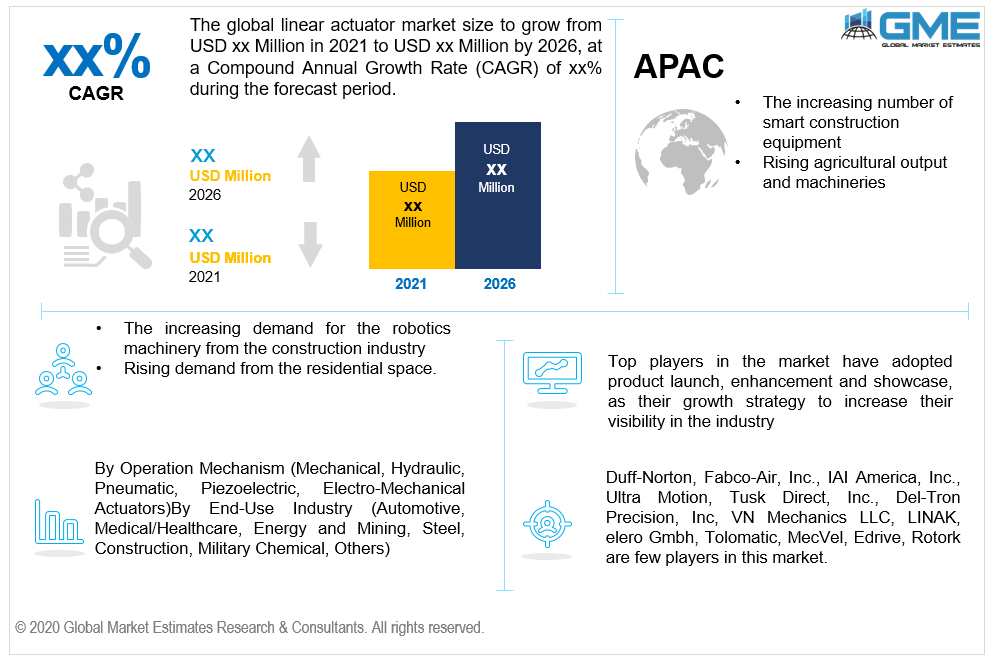

Global Linear Actuators Market Size, Trends & Analysis - Forecasts to 2026 By Operation Mechanism (Mechanical, Hydraulic, Pneumatic, Piezoelectric, Electro-Mechanical Actuators) By End-Use Industry (Automotive, Medical/Healthcare, Energy and Mining, Steel, Construction, MilitaryChemical, Others), By Region (North America, Asia Pacific, Europe, Central & South America, Middle East & Africa); End-User Landscape, Company Market Share Analysis, and Competitor Analysis

The manufacturing sector is highly influenced by industry 4.0. The manufacturing sector’s workload increases with the rising industrial activities. The cost of production increases with the rising industrial activities and the need for seamless conduction of work rises. Linear actuators are then deployed in the manufacturing units to reduce production costs and also improve the automation at the production site.

There has been an increasing trend to integratemanufacturing activities with automation. It is done to simplify the work complexity and to enhance the workers’ productivity. With the rising automation, comes the complex operation/handling of machines and materialsand the need for tools like linear actuators. To fully optimize the handling of materials, linear actuators are exploited at the manufacturing sites.

More need for the linear actuator is seen with the ongoing/persistent use of robotics in the manufacturing space. Roboticmachinery is trending in the manufacturing units as it enhances the production capacity and frees up labor for other important tasks. Integration of humans with robots has been observed to speed up the process and movement of materials from oneend to the other end. Linear actuators enable the easy movement of robots and also allows for the robots to freely engage with the environment. The modern era is revolutionized by the rising penetration ofcomputers, modern printers,and smart machinery to accentuateworkplace speed/output. The use of computers drastically soared in the COVID-19 scenario due to ease of comfort and trending work from home space.Computers use linear actuators for printers and disk drivers for easy motion of 3D printers.

The rising need for automating the work in agriculture and using machinery that uses linear actuators has the potential to enhance work quality. UK and India are emerging as prominent players to record high agricultural output with the help of integrating automation in the agriculture space. Products by the LINAK for agricultural tools help to achieve smart and intelligent solutions for the agricultural output.

As for residential spaces, the product is used to adjust the window positioning. Their application in window automation is highlighted in theskylights, shutters, and casement windows.The food and beverage space too is equipped with the use of the linear actuator to simplify the production processes. Residential spaces can be changed by the integration of actuators to do DIY projects and build tables or shoe-boxes with their help. Residential space is also seeing a rising need for the linear actuator in place of hydraulic as they are more feasible.

In oil and gas, the linear actuator is highly seen as a hot commodity majorly used to regulate the valve pressure. As developed nations engage in a large-scale exploration of oil, the processing and regulation create a positive impact on the use of actuators for smooth functioning. Venture Mfg develops linear actuators suitable for use in oil exploration. The dominance of the Middle East nations in the oil space also adds to the supply of linear actuators in the region. Manufacturers like Rotork are active in supplying the range of actuators in the Middle East to support the oil production units/sites.

The market structure is also shaped by the manufacturer’s effort to seek investments. In April 2020, RISE Robotics was able to raise $3million in funding for the expansion of the product range. The startups are changing the way the products are developed and at what rate. The startups in the robotic space also lead to the use of a linear actuator for the grip on the robot’s movement. Research platforms are organizing conferences at the international level to shed more light on actuator technology creating a large pool of research ideas. Moreover, the manufacturers in this space have introduced and launched screw actuators as the market growing needs for the dynamic product range.

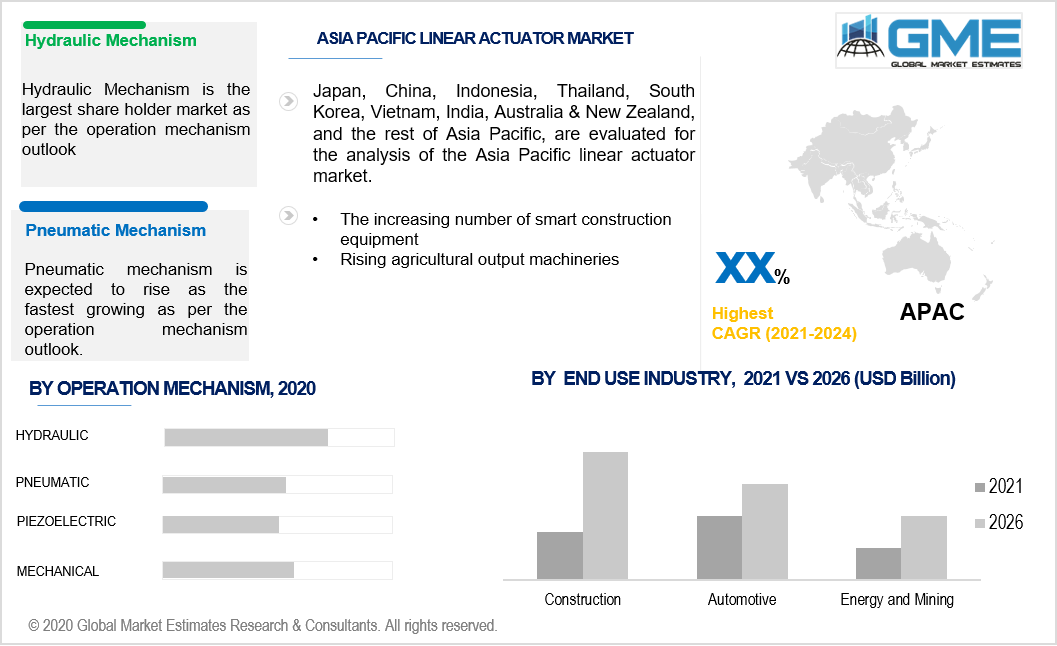

The hydraulic mechanism would account for a major market portion owing to the extended excitation they provide to the machinery used in the control systems. The extended use of such typesof actuators is seen for heavy machinery as they can exert high force. The many advantages of using hydraulic mechanismsare that they can maintain steady torque and force. They have been recommended to be used under harsh conditions where they showcase properties of reliabilityand durability under extreme shocks. They are also used for outdoor manufacturing activities which can be impacted by the harsh temperature range.

The pneumatic mechanism would see a rising trend owing to the efficient cost structure and clean technology they offer.

The construction industry will bear a large-scale use of linear actuators. Construction activities are increasing across the globe owing to the establishment of smart city assignments. The rising need for automation in the industry is also observed owing to theheightened expectation of fast delivery of projects. The use of actuators for the construction equipment leads to the speeding of the projects, increased safety for the workers, and providesa source to handle the heavy load at the site.

The penetration of robots in the automotive space also creates potential applications for the deployment of linear actuators. Additionally, the actuators are used for the regulation of seat adjustment and wheel steering.

North America is presented as a dominant region for the structuring of this market. As the region experiences elevated levels of construction activities and advancement in the automation for manufacturing units would have a positive effect on the market’s rising use of linear actuators.

Asia Pacific is seen as a leader experiencing rising demand for the products in all its industrial units. The region has been experiencing a surging need for solar equipment where linear actuatorsare used to position the panel so it absorbs the maximum sunlight.

Duff-Norton, Fabco-Air, Inc., IAI America, Inc., Ultra Motion,Tusk Direct, Inc., Del-Tron Precision, Inc, VN Mechanics LLC,LINAK, eleroGmbh,Tolomatic,MecVel,Edrive, Rotork are few players in this market.

Please note: This is not an exhaustive list of companies profiled in the report.

In January 2021, LINAK introduced the electric linear actuator equipped with the IO-Link.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Linear Actuators Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Linear Actuators Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS