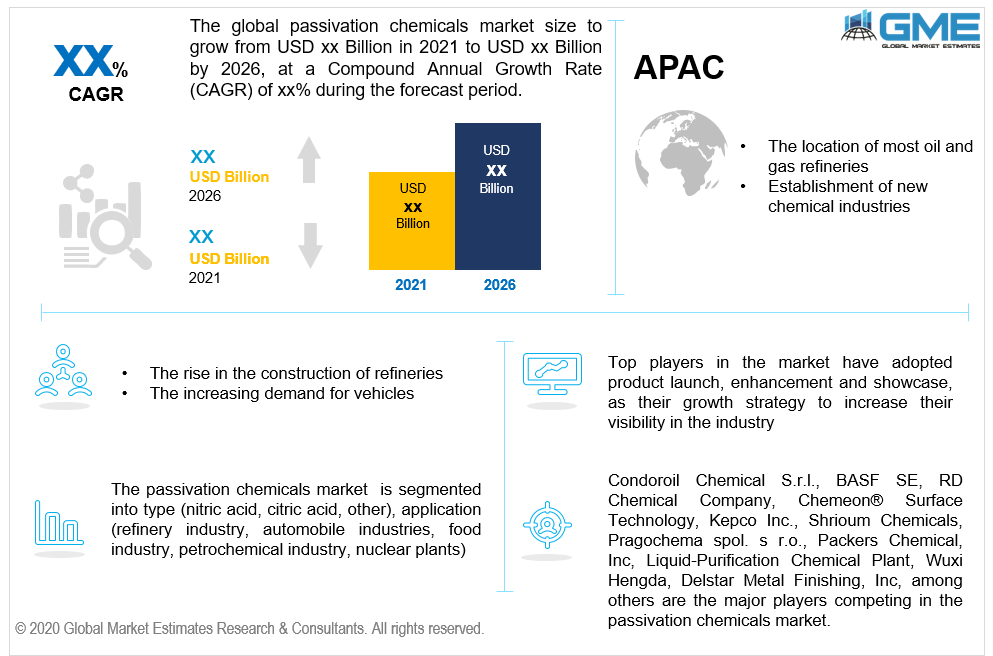

Global Passivation Chemicals Market Size, Trends, and Analysis - Forecasts To 2026 By Type (Nitric Acid, Citric Acid, Other), By Application (Refinery Industry, Automobile Industries, Food Industry, Petrochemical Industry, Nuclear Plants), By Region (North America, Asia Pacific, CSA, Europe, and the Middle East and Africa); End-User Landscape, Company Market Share Analysis & Competitor Analysis

Passivation chemicals are being used to prevent corrosion on metals. The passivation process uses citric acid or nitric acid to remove unwanted iron or any foreign matter from surfaces in stainless steel. This chemical treatment forms a protective oxide layer, which chemically reacts less with air and causes corrosion. Chemical passivation is a two-step process, in which the first step is to remove free iron molecules from the metal's outer surface. In the second step, oxidation is done, which forms a homogeneous protective oxide layer. The chemicals offer various advantages compared to traditional processes including electrical continuity, and plasma-electrolytic oxidation among others. Some of the commonly used passivation chemicals include passivating agent films, organic oils, and inorganic chemical passivates among others. The products are widely preferred by steel industries for coil coating. The chemicals are also used as a protective coating for different machine parts. The growing automotive manufacturing sectors and production of passenger vehicles are boosting the market growth.

Manufacturing companies are using the passivation process for equipment. The stainless steel passivation process is also adopted in magnesium, aluminum, and titanium manufacturing. The passivation process's primary benefits are a chemical film barrier against rust, removal of any kind of contamination from product surfaces, extended life of the products, and reduced need to maintain the components.

The rapid growth in the petroleum refinery and petrochemical industry is supporting the market growth. The equipment in the petrochemical industry is often exposed to various flammable chemicals, causing corrosion and damages to the equipment. Thus, the rise in the construction of refineries is driving the passivation chemicals market.

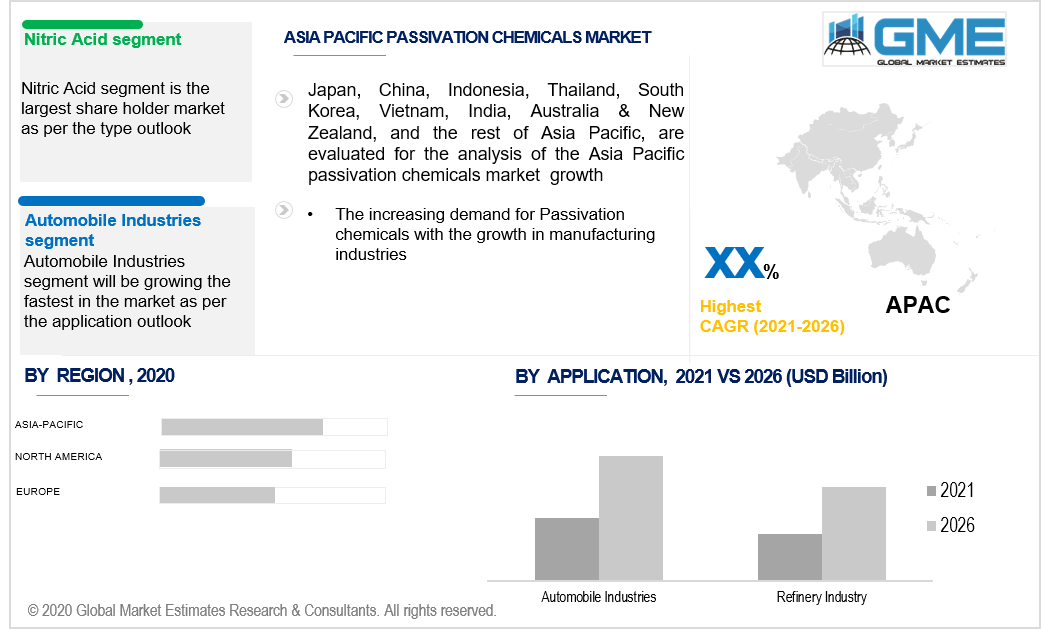

Based on the type, the market is classified and explained into nitric acid, citric acid, and others. The category of nitric acid will be the dominating segment and will occupy the maximum share between 2021-2026, due to its wide usage in stainless steel passivation. Nitric acid is strong compare to other types and helps to dissolves iron molecules existing on the upper surfaces and acts as a most protective coating layer on the stainless steel surfaces.

According to the application analysis, the five segments are the refinery industry, automobile industries, food industry, petrochemical industry, and nuclear plants.

The automobile industry is the prominent industry in the passivation chemicals and generates huge revenue between the forecast period. The automotive parts are coated with passivation chemicals to reduce rusting on the surface and increase the lifespan of the parts. Hence, automotive equipment is exposed to passivation chemicals treatment. As the automotive vehicles market is growing, it is driving the Passivation Chemicals market too. The rising demand for more efficient and cost-effective solutions will drive the growth of this market. Food and Beverage processing and manufacturing equipment is an appropriate target for corrosion and rust. Professional passivation service offers many advantages in food and beverage businesses such as lower maintenance & repair costs, self-healing oxide layer, avoids costly down-time, and increases food safety.

The dominant market segment is held by the Asia-Pacific region in terms of revenue generation. This is attributed to the location of most oil and gas refineries, the establishment of new chemical industries, and the increasing demand for passivation chemicals. As these regions become the hub for industrial developments, there will be more and more demand for passivation processes. Due to Covid-19, these industries have taken an enormous hit, as the production and supply chain was affected. The recovery in growth is expected to be seen earliest by the next quarter, given that the production level will resume for all end-use industries.

The growing automation industry in North American countries such as the U.S., Canada along with the increasing demand for vehicles, is driving the Passivation Chemicals market in the North American region. Similarly, the Europe region is significantly contributing to Passivation Chemicals market growth due to rising automation and the chemical industry.

Condoroil Chemical S.r.l., BASF SE, RD Chemical Company, Chemeon Surface Technology, Kepco Inc., Shrioum Chemicals, Pragochema spol. s r.o., Packers Chemical, Inc, Liquid-Purification Chemical Plant, Wuxi Hengda, Delstar Metal Finishing, Inc, among others, are the significant vendors competing in the Passivation Chemicals market.

Please note: This is not an exhaustive list of companies profiled in the report.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Passivation Chemicals Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Passivation Chemicals Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS