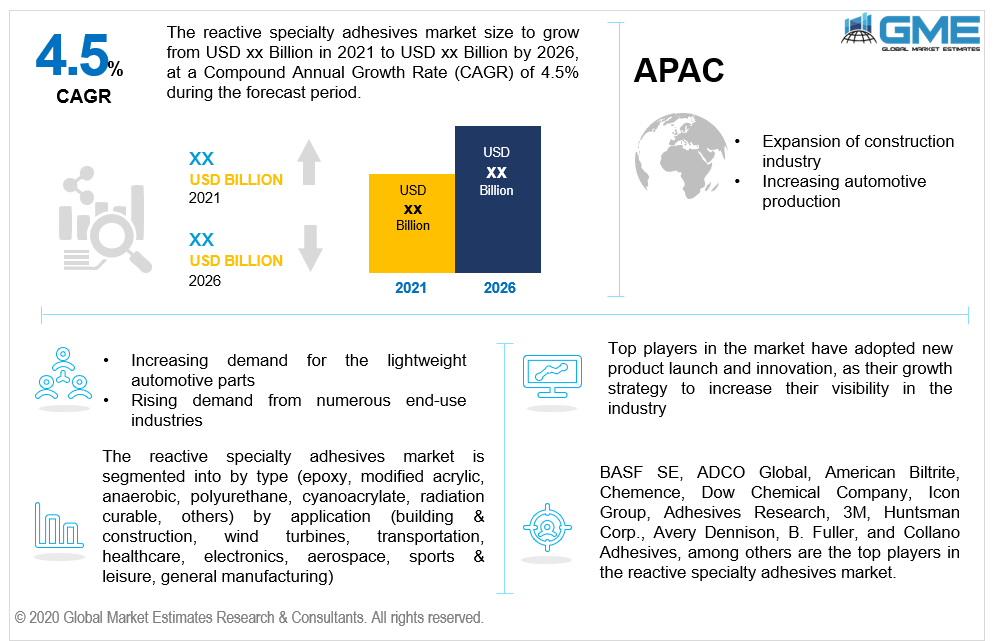

Global Reactive Specialty Adhesives Market Size, Trends & Analysis - Forecasts To 2026 By Type (Epoxy, Modified Acrylic, Anaerobic, Polyurethane, Cyanoacrylate, Radiation Curable, Others) By Application (Building & Construction,Wind Turbines, Transportation, Healthcare, Electronics, Aerospace, Sports & Leisure, General Manufacturing), By Region (North America, Asia Pacific, CSA, Europe, and the Middle East and Africa); End-User Landscape, Company Market Share Analysis & Competitor Analysis

Reactive Specialist Adhesives are viscous dense adhesives that are widely used in commercial applications. Water-based, solvent-borne, radiation adhesives and other forms of reactive specialty adhesives are divided into four categories.Adhesives are substances that join surfaces of at least one item together and opposing their division. Reactive adhesives artificially respond to shape-lasting connections between substrates. This gives the associating areas resistance to synthetic substances, moisture& heat. They come in different assortments relying on the kinds of mixtures, chemical processes, actual cycles, and solvents used to make. Reactive adhesives have higher bond strength and solidness. They have great temperature and natural absorption capacity, much under brutal conditions. They can likewise be utilized as coatings and sealants.

Reactive Specialty Adhesives are thick gooey cement that is regularly used for business purposes. Reactive Specialty Adhesives are arranged into four sorts which incorporate waterborne, dissolvable borne, radiation cement, and others. A portion of the crude materials which are needed for the detailing of reactive specialty adhesives includes styrene-butadiene elastic, melamine-formaldehyde, and polyvinyl alcohol, among others.

Reactive Specialty Adhesives are essentially utilized in the automotive business for sheet molding, rooftop lining, coating, glazing, and seat unit bonding. Polyurethanes and modified acrylics are two of the most popular reactive specialty adhesives used in the assembly of automobiles and other vehicles. Reactive specialty adhesives are now being used in consumer electronics and the building and construction industries.

The demand for vehicle assembly is regarded as an excellent factor influencing the market development of sensitive claims to fame cement. This is due to the fact that Reactive Specialty Adhesive is a critical component in the bonding of various inside and outside segments made of steel, aluminium, polymers, textures, and other materials.Furthermore, the growing emphasis on eco-friendliness and vehicle discharge control has prompted an increase in demand for lightweight car parts, which has resulted in an interest in reactive specialty adhesives.Also, reactive specialty adhesives are commonly used as a component of a wide range of manufactured products, for example, medical services equipment, car parts, and sports equipment, among others. It is required to increase demand for reactive specialty adhesives from end-use industries.

Expanding construction activities in the residential,commercial, and medical sectors, among others, are driving up demand for reactive specialty adhesives around the world. The enhanced chemical and mechanical properties that it possesses are a significant market driver.Also, the usage of reactive adhesives in the automobile industry has been one of the major factors driving this market. Moreover, the automobile industry is growing at a very high rate owing to various growing manufacturing units established in various parts across the globe.

Based on the type segment the market is segmented intoepoxy, modified acrylic, anaerobic, polyurethane, cyanoacrylate, and radiation curable, among others.The epoxy segment is expected to hold the largest shareholder in the market in terms of volume and revenue over the forecast timeline. Epoxy is a thermosetting polymer with improved mechanical and obstructive properties. The term epoxy can refer to the relieving end product as well as some of the critical components used in epoxy pitches.

Polyurethane is projected to increase at the fastest rate in the reactive specialty adhesives market during the forecast period.Polyurethanes are one of the most commonly used reactive adhesives for assemblingthe car and other vehicle components.Polyurethane adhesives are gaining popularity in the home building industry due to their ability to adhere to a wide range of substrates, including plastic, glass, wood, and concrete. Typically, two-part polyurethane adhesives are used to bind ceiling drywall to roof rafters.

Based on the application segment, the market is bifurcated into eight sectors including; building & construction,wind turbines, transportation, healthcare, electronics, aerospace, sports & leisure, and general manufacturing.In terms of value and volume, the building & construction segment dominates the reactive specialty adhesives industry.Growing demand from the non-residential and residential sectors, government incentives for affordable housing to improve construction activity, and ongoing infrastructure projects have been key factors that drive the reactive specialty adhesives market's rapid expansion.As a result, there is an increase in demand for chemicals that add value to building activities, such as specialty cement additives, polymer-based grouts, silicone caulks, and mortars.

Adhesives are also used in a variety of applications in healthcare, ranging from clinical device assembly to interior and exterior clinical applications. Sewing, for example, is being phased out in favor of superior cyanoacrylates for closing skin wounds.

As per the geographical analysis, the market of reactive specialty adhesives can be classified into North America, Asia-Pacific, Europe, Middle East & Africa, and Central South America. North America region is projected to hold the largest market share in the reactive specialty adhesivesmarket owing to the increasing investments in real estate and increasing automotive industryin the region. Furthermore, Asia Pacific is accounted to be the fastest-growing market with a CAGR owing to the end number of construction activities in China and India.The automotive and transportation industries are significant users of reactive specialty adhesives in this region.The APAC region's economic growth, especially in emerging markets such as India, Malaysia, and Vietnam, is leading to an increase in the number of infrastructure projects, which is anticipated to drive demand for reactive specialty adhesives in building and construction applications.

BASF SE, ADCO Global, American Biltrite, Chemence, Dow Chemical Company, Icon Group, Adhesives Research, 3M, Huntsman Corp., Avery Dennison, B. Fuller, and Collano Adhesives, among others are the top players in thereactive specialty adhesives market

Please note: This is not an exhaustive list of companies profiled in the report.

In September 2019, Lanxess developed an isocyanate urethane system with low free (LF) isocyanates for sealants, adhesives, and one-component foams. The new device would increase the development of reactive adhesives using isocyanate prepolymer technology, which will ultimately lead to an increase in revenue

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Reactive Specialty Adhesives Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Reactive Specialty Adhesives Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS