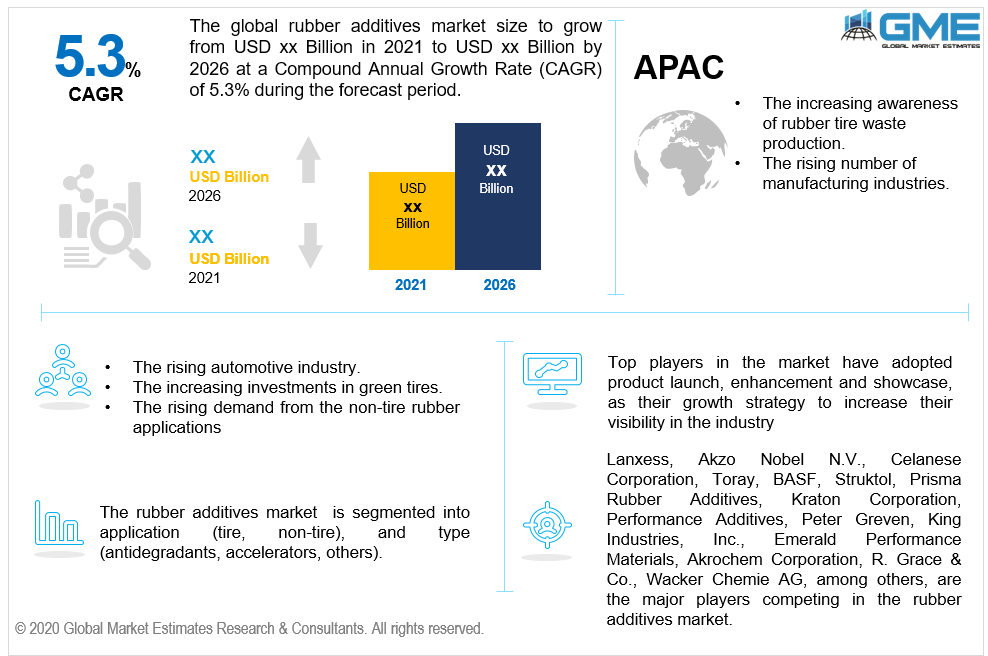

Global Rubber Additives Market Size, Trends, and Analysis - Forecast To 2026 By Application (Tire, Non-Tire), By Type (Antidegradants, Accelerators, Others), By Region (North America, Asia Pacific, CSA, Europe, and the Middle East and Africa); End-User Landscape, Company Market Share Analysis & Competitor Analysis

Rubber Additives are used during the manufacturing phase of natural and synthetic rubber products to imbue the products with the desired properties. Rubber additives are rubber polymers that have been treated with the addition of chemicals to improve or boost their overall efficiency. They are widely used in industrial engineering and processing because of their high viscosity and cross-linking capabilities. They serve the rubber industry with a diverse range that includes processing chemicals, high-performance tire bladders, and anti-sun check waxes, among others.

Accelerator rubber additives are used to increase and maximize the rubber's cross-linking performance during the vulcanization process. Vulcanization is a method that increases the durability or strength of rubber by adding sulfur-based additives. Adhesion enhancers are often used in the production stage to increase the adhesion of rubber to metals and thereby the integrity of the finished product.Rubber compounds such as processing assist enhancers are used to reduce the viscosity of rubber until it is shaped into the desired form. Manufacturers can improve the rubber's consistency with other parts in the finished product by lowering the viscosity of the liquid rubber.

Rubber extender additives are used to enhance the insulation properties of the material. These compounds, such as esters and fatty acids, boost rubber's ability to tolerate elevated temperatures and voltage. Rubber goods used as insulators and rubber tires include this. Rubber's excellent insulating properties make it a common application for rubber goods.So, for rubber insulators the ability to withstand high voltages is essential. In the case of rubber tires, they’re exposed to high temperatures when the vehicle is in motion as the friction causes them to heat up rapidly. By improving the thermal stability of rubber tires, the tires will not expand when it’s under tremendous heat when the vehicle is moving and prevent rupture of tires. Vulcanization inhibitor rubber additives are used to inhibit or reduce the vulcanization process occurring in rubber once the desired amount of cross-linking of the rubber polymer, which translates to the strength of the rubber product has been attained.

The demand for rubber products in the car industry has fueled the growth of the rubber additives market. Automobiles rely on rubber tires and other rubber-based materials for their needs, such as tubings, insulation, belts, and other items. Rubber tires will remain the most widely used rubber commodity in the automotive industry, and no other product will substitute them.Rubber additives are in greater demand in the tire manufacturing industry, as higher quality rubber tires with distinct properties such as improved longevity, high thermal tolerance, and other properties are desired.The demand for rubber tires in the automotive industry, as well as insulators, conveyor belts, and other rubber-based products in various industries, is driving the rubber additives market.

The economy is being stifled by ever-increasing environmental legislation. Rubber tires, which are non-biodegradable and long-lasting, are becoming an environmental issue in every region. This has resulted in a rise in the market for recycled tires, as well as improvements in their reliability to ensure that they can be used for longer periods. These factors have acted as significant roadblocks to the tire industry's expansion, negatively impacting the economy.

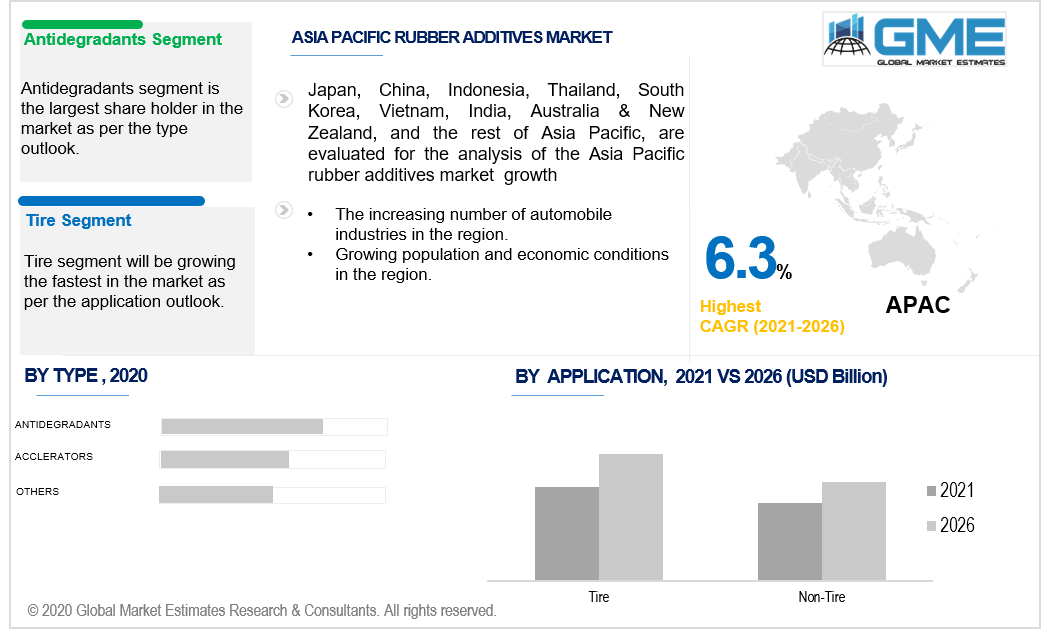

Based on the application of rubber additives in various industries, the rubber additives market can be segmented into tire and non-tire. Tires are the most popular rubber-based materials in use around the world, and the automotive industry relies heavily on them to guarantee the durability of its cars. During the forecast era, the tires segment is projected to hold the largest share of the rubber additives market and expand at the fastest pace.The growing demand for vehicles is the primary driver for this segment, and the need to improve the performance of rubber tires by rubber additives is projected to push up the demand for rubber additives in the automotive industry.

Based on type, the rubber additives market can be segmented into antidegradants, accelerators, and others. During the forecast period, the antidegradants segment is expected to dominate the industry. The need for extremely durable rubber tires with a longer life cycle has grown as environmental issues around recycled rubber tires have grown. Antidegradants are used to prevent tires from degrading due to normal wear and tear and to extend their life span so that they can be used for longer periods and produce less pollution. During the forecast period, the increased demand for more resilient tires will be the primary driver for the antidegradants market.

The rubber additives industry is dominated by North America. The region's high demand for automobiles has boosted demand for rubber tires and, as a result, rubber additives. The region's stringent tire recycling regulations, as well as efforts to improve the tire life cycle, are expected to boost demand for rubber additives in the industry.

The APAC region is expected to grow at the fastest rate during the forecast period. The growing population in the region combined with the increase in economic conditions has increased the demand for automobiles and thereby the rubber tires in the region. The region especially China and India is becoming a major manufacturing hub for automobiles in the world and has increased the demand for rubber additives in the region.

The region has also seen an increase in manufacturing industries which has also increased the demand for other rubber products because of their insulation properties and elasticity. Rubber additives are used to improve these properties and are expected to improve the demand for rubber additives in the region.

Prisma Rubber Additives, Lanxess, Celanese Corporation, Akzo Nobel N.V., Struktol, Kraton Corporation, Performance Additives, Peter Greven, King Industries, Inc., BASF, Emerald Performance Materials, Akrochem Corporation, Toray,R. Grace & Co., Wacker Chemie AG, among others, are the major vendors competing in the rubber additivesmarket.

Please note: This is not an exhaustive list of companies profiled in the report.

In March 2021, Celanese Corporation recently expand its capacity for compounding engineered materials at three Asian manufacturing plants: Nanjing, China; Suzhou, China; and Silvassa, India.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Rubber Additives Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Rubber Additives Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS