Global Spunbond Nonwovens Market Size, Trends & Analysis - Forecasts to 2026 By Material Type (Polyester Spunbond Nonwovens, Polypropylene Spunbond Nonwovens, Polyethylene Spunbond Nonwovens and Others [Polyamide Spunbond Nonwovens, Polylactic Spunbond Nonwovens, Polyurethane Spunbond Nonwovens, and Bico Spunbond Nonwovens); By End-user (Medical, Personal Care & Hygiene, Agriculture, Automotive, Packaging, and Others [Geotextile, Construction, and Filtration]); By Function (Disposable, and Durable); By Region (North America, Europe, Asia Pacific, MEA, and CSA); End-User Landscape, Vendor Landscape, and Company Market Share Analysis & Competitor Analysis

Spunbond nonwovens are manufactured by using spunbond technology, in which thermoplastic polymers are pushed out to form filaments of fine fibers having a diameter of about 15-35 micrometer. The filaments are then collected and bonded using chemical, heat, or mechanical treatment to form a web or sheet out of it. Owing to high strength, high molecular weight, and a wide spectrum of molecular weight distribution polypropylene, polyethylene, and polyester are widely used as raw materials.

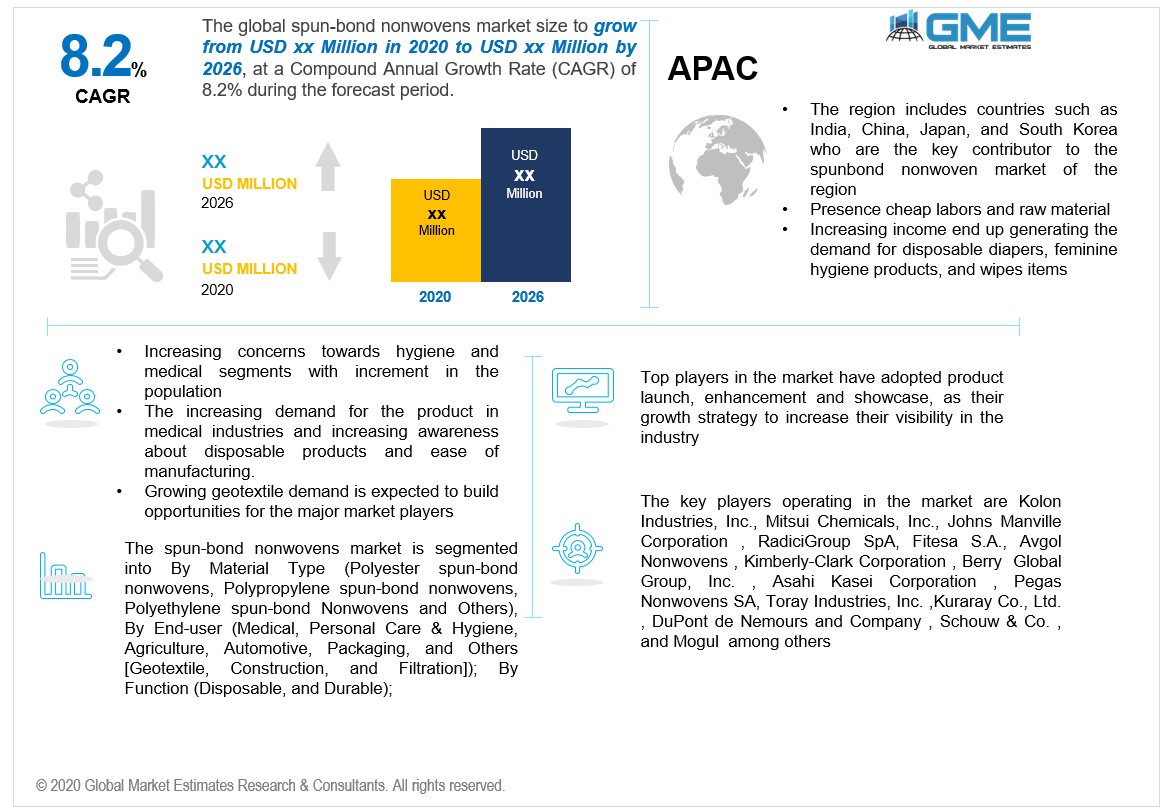

The spunbond nonwovens market is projected to achieve its market peak in the middle of 2020-2026 at a CAGR of 8.2%. Increasing concerns towards hygiene and medical segments with increment in the population are directly proportional to the demand for spun-bond nonwovens demand in recent times. The market of spun-bond nonwoven is further expected to get boosted up in the projected years due to the increased demand for the product in medical industries and increasing awareness about disposable products and ease of manufacturing. Growing geotextile demand is expected to build opportunities for the major suppliers in the coming years.

However, the requirement of skilled technicians and high initial investment are the challenges that might hurdle the growth of the spun-bond nonwoven market.

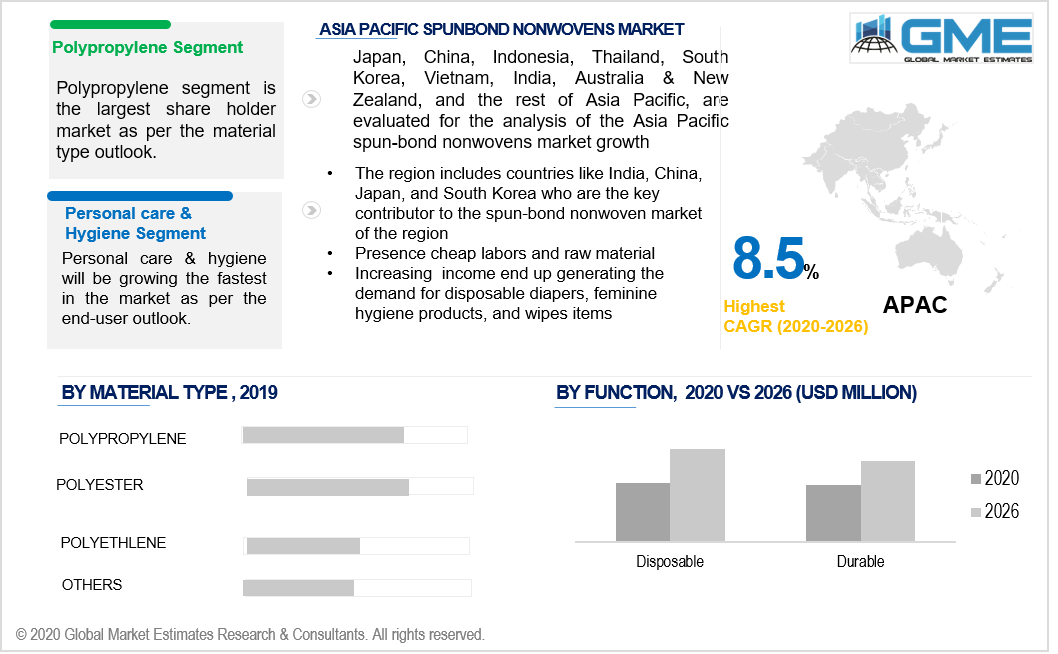

The material used to manufacture the spun-bond nonwovens can be studied as polyester, polyethylene, polypropylene, and others. Polypropylene is the fastest-growing segment and projected to maintain the market growth momentum in the coming years also. The prime reason behind the significant growth of the market is the rising popularity of the segment among various end-users such as personal care & medical hygiene, and agriculture in some cases. The propylene segment has a high melting point and gets softens sufficiently to bond to one another without dismantling the properties of the original fibers which acts as an advantage for its end-user applications.

Medical, personal care & hygiene, agriculture, automotive, packaging, and others are the bifurcations of the end-users of the spun- bond nonwovens. Out of the mentioned segment personal care & hygiene is the fastest-growing end-user segment followed by the medical segment. Spunbond nonwovens offer major properties such as resiliency, absorbency, stretchability, washability, and bacterial resistance & sterility which made it favorable to use in the personal care & hygiene segment.

Disposability and durability are the two function segments of spun-bond nonwovens. The disposable segment is the dominating segment of the spun-bond nonwovens market as compared to the durable segment. This segment is in great demand among various end-users such as medical, personal care & hygiene. Affordability of the segment and can discard of after every use is the reason behind the market demand of the disposable segment.

Asia-Pacific is estimated to show the fastest market of the spun-bond nonwoven market. The region includes countries like India, China, Japan, and South Korea who are the key contributor to the spun-bond nonwoven market of the region. Presence cheap labors and raw material make it feasible for the manufacturers to expand their business in the region which makes the region to be the fastest-growing region. Increasing income end up generating the demand for wipes items, and feminine hygiene products, thus accelerating the growth of the product’s market

The key players operating in the market include Kolon Industries, Inc., Mitsui Chemicals, Inc., Johns Manville Corporation, Fitesa S.A., Kimberly-Clark Corporation, Berry Global Group, Inc., Asahi Kasei Corporation, RadiciGroup SpA, Pegas Nonwovens SA, Toray Industries, Inc., Kuraray Co., Ltd., Avgol Nonwovens, DuPont de Nemours and Company, Schouw & Co., and Mogul among others.

Please note: This is not an exhaustive list of companies profiled in the report.

In November 2020, Schouw & Co. (Denmark) strengthen its position in personal care by expanding its production facilities in Malaysia and the US. The company invested around DKK 250 million in building two production lines. A specialty nonwoven line is built in Malaysia and a print line in the US and both the lines are projected to run by the second half of the year 2021.

In November 2019, Avgol Nonwovens has pushed its limit by bringing its pioneering waveform 3D solution in the North American market to meet the region's hygiene demand by adding values to their product.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Spunbond Nonwovens Market has been studied from the year 2017 till 2026. However, the CAGR provided in the report is from the year 2018 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply side analysis for the Spunbond Nonwovens Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the companies and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS