Global Textile Machinery Market Size, Trends & Analysis - Forecasts to 2026 By Type (Textile Process Machineries [Cloth Finishing Machines, Knitting Machines, Fabric Seaming machineries, Crochet Machines, Lace Making Machines, Label Making Machines, Quilting Machines, Textile Finishing Machines, Textile Sourcing Machines, Textile Spinning Machines, Textile Winding Machines, Textile Edge Control Machines, Thread Winding Machines, Weaving Machines, Zipper Making Machines, Woollen Mill Machines], Textile Working Machineries and Equipment’s and Accessories [Applique Scaling Machines, Attaching Machines, Cloth Cutting Machines, Embroidery Machinery, Garment Machinery, Industrial Sewing Machine, Laundry Dryers, Monogramming Machines, Textile Bleaching Machines, Textile Folding Machine, Textile Trimmers Machine]), By Device (Balers, Draw Frames, Fabric Cutters, Calenders, Dyers, Dryers, Padres, Extruders, Conveyers, Die Presses), By Raw Material (Cotton, Wool, Nylon, Polyester, Acrylic, Silk, Others), By End-User (Cotton Mill, Garment Factory, Wool Mill, Textile Industry), By Region (North America, Asia Pacific, Europe, Latin America, Middle East & Africa); End-User Landscape, Company Market Share Analysis, and Competitor Analysis

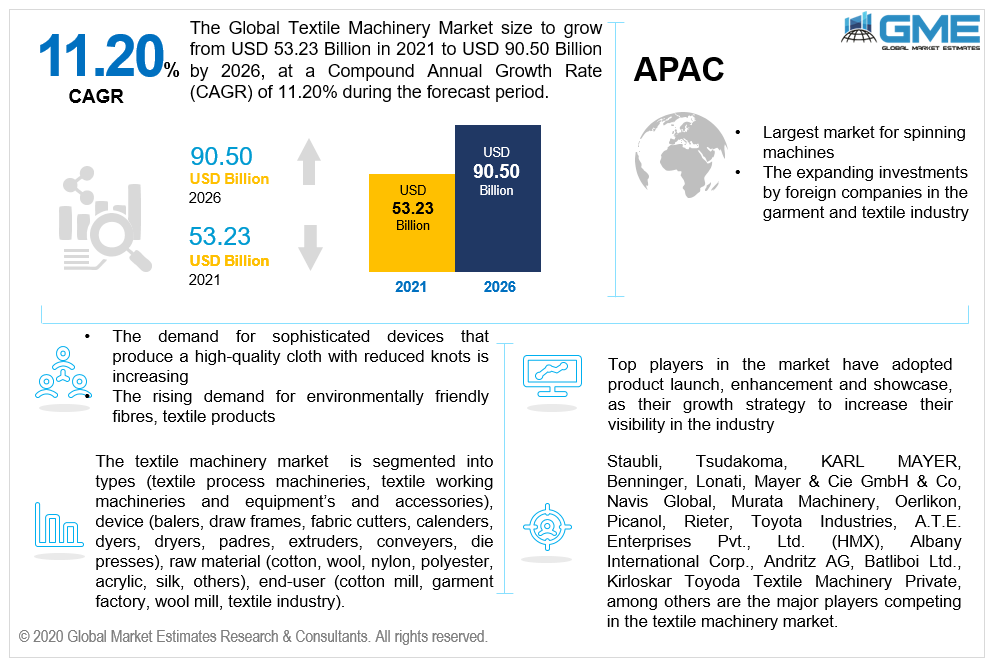

Textile machines are used for processing textiles, woven & non-woven materials, and fabrics among others. They are used for performing different activities like spinning, dyeing, weaving, and warping. Textile equipment is used to dye, manufacture, and finish materials like yarn, fibre, and thread. The growing demand for Non-Woven Fabrics is driving the market for textile machinery. The rising demand for environmentally friendly fibers, textile products, and growing demand from developing nations will stimulate market growth.

The growing demand for sophisticated devices that produce high-quality cloth along with advancements in printing technology in textile manufacturing is supporting the market growth. The growing adoption of automation and robotics in textile manufacturing is also propelling the market for textile machinery.

Today machinery manufacturers deliver sophisticated machines of higher production capacity and speed and textile machinery at competitive prices. Several small-scale market players also make the machinery sector more competitive, and multinational corporations have entered the global market, escalating the competition to the next level and driving companies to work on their innovation and productivity. The textile machinery market is extremely dynamic, changing from conventional to more sophisticated options owing to continuous technological advancements. The increasing market demand for furniture upholstery, home textiles, fashion trends, and automobile textiles also affects textile machinery's demand.

Based on the type, the market is considered into two segments namely textile process machinery and textile working machinery. The textile process machinery is further sub-segmented into, cloth dying machines, textile spinning machines, knitting machines, quilting machines, crochet machines, textile finishing, lace-making machines, textile sourcing machines, and label making machines among others.

The textile working machinery and equipment’s has further explained into applique scaling machines, monogramming machines, attaching machines, industrial sewing machine, cloth cutting machines, and embroidery machinery, among others.

The textile spinning machines segment will be the dominating segment in terms of share between 2021-2026. They are broadly used due to the quality of yarn and the high speed it produces. This technology makes structurally stronger yarns, produces softer fabrics and yarns, and can spin any material. The operational functions are also very simple to understand and learn. Moreover, as the drawing section's speed can be appropriately managed, the yarn's uniformity is very well maintained.

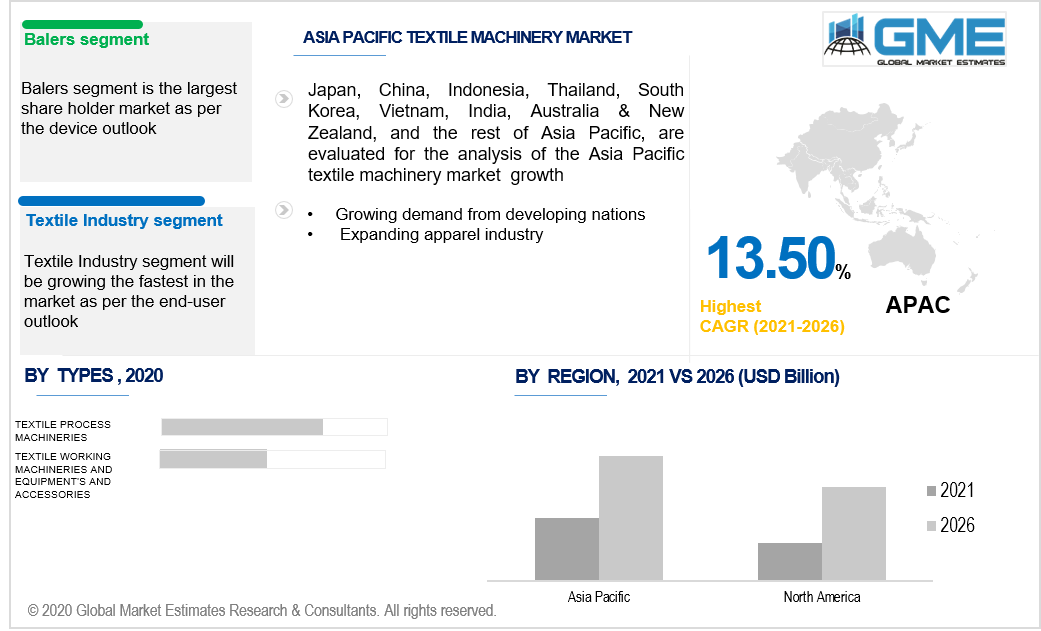

Based on the devices, the market is categorized into balers, die presses, draw frames, conveyors, fabric cutters, extruders, padres, and dryers among others. The balers segment will witness significant growth in the forecast period. A baler machine is a valuable device used as recycling equipment. The press-fitted within the baler compresses together waste materials, like cardboard, which are then tied together to form a bale.

Based on the raw material, the market is categorized into seven segments namely cotton, wool, nylon, polyester, acrylic, silk, and others. The cotton segment will occupy the major chunk of the market between the forecast period. Cotton is a primary textile for the fashion industry. It is a fixture of the textile industry because of its soft feel, mass production, durability, and absorbency. It is commonly used for blue jeans, T-shirts, sweats, dresses, and so much more.

By end-user, there are four segments: cotton mill, garment factory, wool mill, and textile industry. The textile industry will have the highest CAGR in the forecast period. Technical textiles will be growing the fastest and the most capable areas under the larger textile industry.

The Asia Pacific region will be the key region in the global market and occupy a major share in spinning machines. The expanding investments by foreign companies in the garment and textile industry are important factors driving the region's market growth. India, China, Vietnam, Japan, and Indonesia are the main markets for textile machinery in the Asia Pacific region. The presence of key textile industries and rising demand for clothing are supporting regional growth. Increasing investments in textile industries from the multination companies in Indian also driving regional growth.

American Textile Machinery Association, YIINCHUEN Machine, Dornier, NEDCO, Salvadè, Bonas, Lakshmi Machine Works, Marzoli, STOLL, Truetzschler, RIFA, Golden Eagle, JINGWEI, ERFANGJI, NGGONG, PACIFIC MECHATRONIC, QINGDAO SPARK GROUP, Qingdao Textile, DONGJIA, JINSHENG, CTM, CHONGLEE MACHINERY, Intertrad Group, Itema Group, Staubli, Tsudakoma, KARL MAYER, Benninger, Lonati, Mayer & Cie GmbH & Co, Navis Global, Murata Machinery, Oerlikon, Picanol, Rieter, Toyota Industries, A.T.E. Enterprises Pvt., Ltd. (HMX), Albany International Corp., Andritz AG, Batliboi Ltd., Kirloskar Toyoda Textile Machinery Private, Brother Industries Ltd., C. A. Litzler Co., Inc., Cheran Machines India Pvt., Ltd., China Hi-Tech Group Corporation, Cortex, CPM Wolverine Proctor LLC are some of the identified industry players.

Please note: This is not an exhaustive list of companies profiled in the report.

We value your investment and offer free customization with every report to fulfil your exact research needs.

The Global Textile Machinery Market has been studied from the year 2019 till 2026. However, the CAGR provided in the report is from the year 2021 to 2026. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the Textile Machinery Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS